Previous

Next

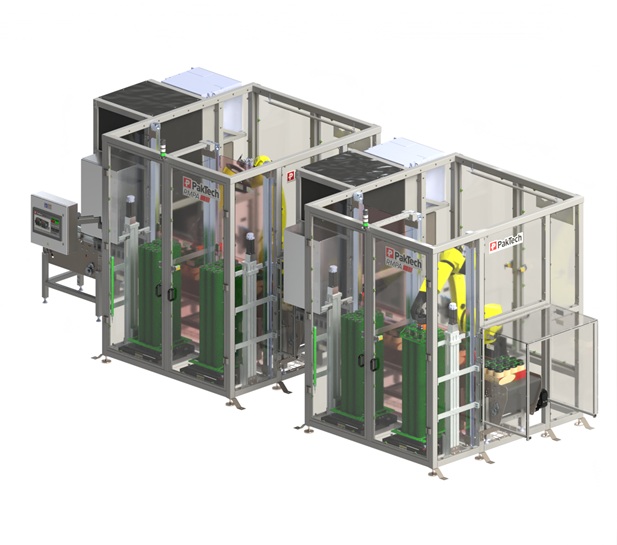

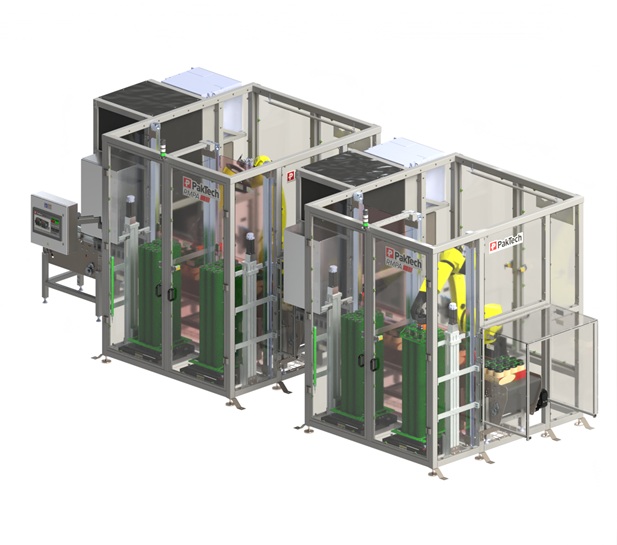

RMPA

Features:

Safe

Risk assessed. UL listed industrial controls enclosure constructed to NFPA 79 standards.

Smart

Modular design for 1-, 2-, or 3-robot machines. Two magazines per robot for extended runtimes. Vision-based case tracking for accurate handle application.

Simple

Up to 60 cycles per minute for a two-robot machine. Selectable in-line bypass mode to allow product pass through RMPA conveyor.

Financing Available. Learn More

SPECIFICATIONS

Design

- Six-axis FANUC robot arm(s) to pick and apply PakTech Handles

- Modular Design for 1-, 2-, or 3-robot machines to match required speeds

- Two magazines per robot for extended runtimes

- Selectable in-line bypass mode

- Quick-change end of arm tooling and tool-less magazine changeover

- UL Listed controls enclosure constructed to NFPA 79 standards

- Infeed cameras for vision-based case tracking

Standard Components

- Allen-Bradley Panelview™ HMI

- Allen-Bradley CompactLogix™ PLC

- Allen-Bradley PowerFlex™ variable frequency drives

- Allen Bradley Kinetix™ servo drives

- Allen Bradley VPL servo motors

- SEW-Eurodrive conveyor drive gear motors

- Intralox® tight transfer conveyor belt

- Festo pneumatic components

- Brushed stainless steel welded frame

- Stainless steel NEMA 4X controls enclosures

- Ewon Flexy industrial remote connectivity*

Utilities

- 480 VAC +/- 10% 3 Phase, 50 Amps electrical power supply required

- 80 PSI – 150 PSI compressed air supply @ 5 CFM

- Ambient temperature 32°-100°F (0°-38°C)

- Ambient humidity lower than 75%, with no condensation or frost allowed

- Low backpressure upstream conveyor required

OPERATION

- Operator required for manual loading of handle magazines

- 10-minute handle reload time per magazine (typical)

- Two independent magazines per robot

- Product specific settings stored in recipes on the HMI for fast product changeover

- Tool-less magazine changeover and quick-connect application head

OPTIONS

- 1-, 2-, or 3-Robot systems available

- Handle, barcode, and/or product inspection at applicator outfeed

- Intralox DARB™ product reject at machine outfeed (requires inspection system)

- Available conveyor heights from 24 inches (610mm) to 40 inches (1010mm)

- Left-to-Right or Right-to-Left product flow

- Advanced lighting package including interior and area lighting

RELATED HANDLES

VIDEO

The PakTech Applicator Difference

PakTech applicators are more than just automated packaging machines.

They are the Safe, Smart, Simple, and Efficient way to package your product. That’s the PakTech difference.

Each machine revision is processed through a formal risk assessment. UL and CE certifications available

PakTech applicators are a dependable, durable part of your operation. The smart way to package your product for market.

Designed with ease of use in mind, our applicators are straight forward and intuitive to operate. Simply the right choice to package your product.

Efficient and effective, PakTech applicators run every single day – 24-7.